Bạn muốn in ấn gì ?

Premium Canvas Bag Printing in Vietnam - Custom Canvas Bags by Alona

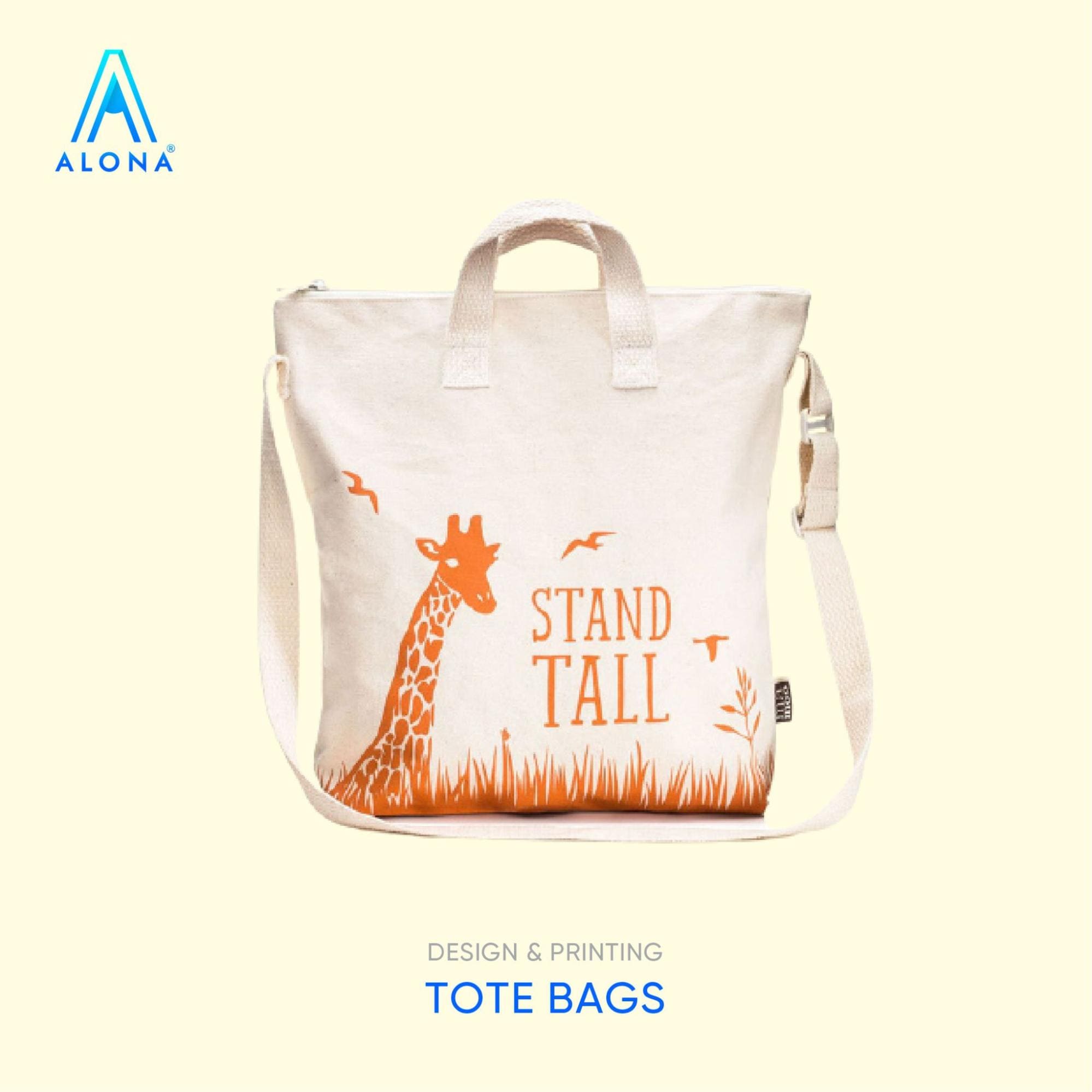

Canvas bags are increasingly popular thanks to their durability, eco-friendliness, and ease of custom design. However, for high-quality canvas bag printing and a finished product, you need to understand key factors such as material, weight, size, printing techniques, and bag finishing. In this article, Alona will help you explore the details of each element that constitutes a beautiful and durable canvas bag.

Materials, Sizes & Features in Canvas Bags

To select the optimal Canvas bag, a detailed analysis of its constituent components is necessary. We will carefully examine the following important factors:

Canvas Fabric Weights & Types

Choosing the optimal canvas fabric for a bag depends on the fiber composition (which affects the properties) and the fabric weight (which affects the load-bearing capacity).

Canvas Fabric Types:

- Hemp Canvas: This fabric offers superior durability, is eco-friendly, resistant to mildew, and has good heat resistance. It is often used for high-end products or outdoor bags due to its high load capacity.

- Cotton Canvas: Woven from natural cotton fibers, it is soft, breathable, and safe for skin. This is the most commonly used fabric for printed logo bags or gift bags due to its ability to display print colors clearly and maintain structure.

- Linen Canvas: A natural material with high durability, good abrasion resistance, and minimal shrinkage after washing. Linen provides a refined, elegant look, often used for premium fashion bags or high-end handmade bags.

- Synthetic Canvas: Typically a blend of synthetic fibers like polyester and nylon, enhancing water resistance, wrinkle resistance, and mechanical strength. Suitable for school bags, travel bags, or products requiring high protection features.

Classification by Weight

- Light-weight Canvas (4-7 oz/m²): Thin, light, and soft fabric, suitable for decorative products, small pouches, or foldable bags.

- Medium-weight Canvas (8-12 oz/m²): Medium thickness, durable and strong, used for sewing tote bags, handbags, shoes, or uniforms.

- Heavy-weight Canvas (13-20 oz/m²): Thick fabric with good load-bearing capacity, suitable for travel bags, heavy-duty utility bags, or outdoor items like tents.

- Extra-heavy-weight Canvas (>20 oz/m²): Extremely thick, super durable fabric, used for specialized products such as mountaineering backpacks, sacks, or protective gear.

Bag Size, Shape & Structure

Determining the size, shape, and structure is an essential step in the custom canvas bag production process:

- Material: Canvas (also known as Vải bố or Vải bạt) is a thick, woven fabric with high mechanical strength, originally often made from hemp fiber. The fabric is characterized by thick, tight, woven fibers in a rough mesh, which helps the product be less permeable to water and have good load-bearing capacity.

- Bag Styles: Tote bag, wine carrier bag, drawstring bag, mango-shaped (die-cut handle) bag.

- Color: A wide range of color options are available based on customer choice.

- Size:

Bag Style | Dimensions (Height x Length x Gusset/Depth) | Intended Use |

Horizontal | 230 x 280 x 75 mm | Gift bags, small book carriers. |

Horizontal | 230 x 330 x 90 mm | Horizontal A4 document bags, medium-sized fashion bags. |

Horizontal | 320 x 380 x 100 mm | Shopping bags, large laptop/document bags. |

Vertical | 140 x 130 x 60 mm | Cosmetic bags, small utility items. |

Vertical | 400 x 300 x 90 mm | Magazine bags, books, files/folders. |

Vertical | 410 x 290 x 100 mm | Standard Tote bag, for laptop, promotional items. |

Handle Options

Customers can choose one of the following popular styles:

- Traditional Tote Straps: Double straps, sewn permanently, suitable for hand-carrying or shoulder-wearing. Often made from the same canvas material or woven cotton webbing.

- Cross-body Strap: A long strap, with an adjustable buckle for flexible length adjustment, increasing versatility for cross-body or shoulder wear.

Printing Techniques & Finishes for Canvas Bags

Canvas Bag Printing Techniques

Silk screen printing

This is a traditional printing method that uses a mesh stencil (screen) to transfer ink onto the fabric bag.

- Pros: Very low cost for large volume printing (from 100 bags up). The printed color is durable over time and is ideal for simple, low-color logos.

- Cons: High mold cost for each color (each color requires a separate screen), only suitable for $1-3$ color designs. This method cannot accurately render fine details, complex images, or gradients.

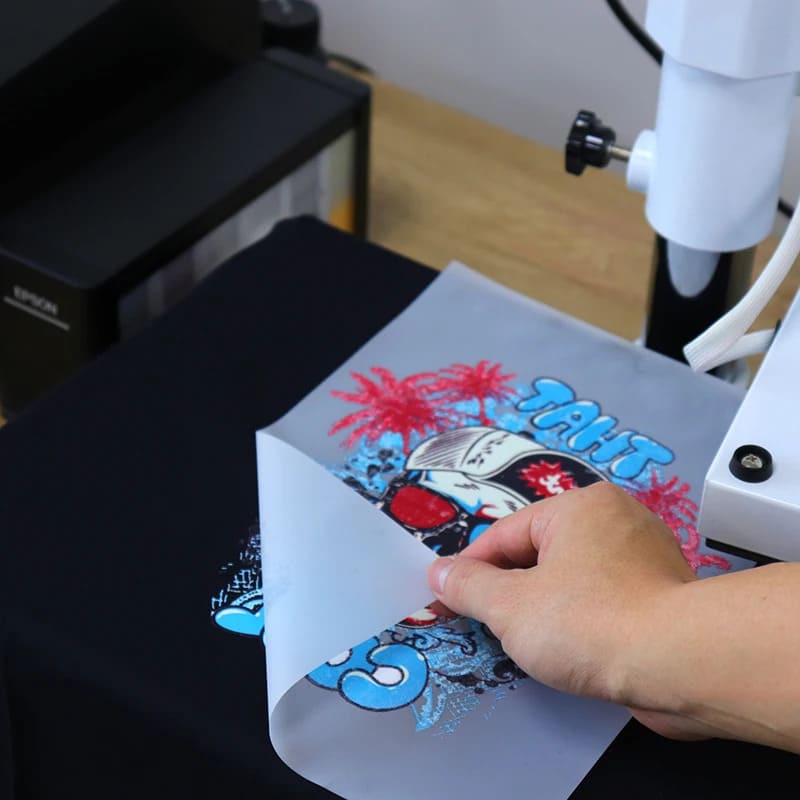

PET Heat transfer printing (PET film printing)

A modern technology that uses a pre-printed PET film or paper, which is then heat-pressed onto the fabric bag.

- Pros: Sharp print quality, vibrant colors, and high detail representation. Good durability, resistance to peeling, water, and sunlight. Can print multiple colors, suitable for complex designs, and applicable to various fabric types.

- Cons: Multi-step process can be time-consuming. Print durability may decrease if washed with strong detergents or too frequently.

Traditional heat transfer printing

This method works by pressing logos or images from a transfer paper onto the canvas bag using high temperatures.

- Pros: Allows printing of complex, multi-colored logos and images. Suitable for businesses needing small volume printing on short notice. Products maintain excellent color fastness, resist peeling, and are water-resistant. The operation is relatively simple.

- Cons: The per-unit cost increases when printing thousands of bags. Prints are prone to fading or peeling after many washes. This method works best only on white and cream-colored canvas fabrics.

Digital Printing

A modern printing technology that allows direct printing of images from a computer onto the bag surface without needing to create a mold.

- Pros: Perfect for designs with many colors, complex details such as photographs or gradient effects. There is no limit on the number of colors. Shortens production time and is suitable for small volume orders.

- Cons: High cost when ordering in large quantities. The printed image may fade faster after frequent washing compared to silk screening. Some canvas types may not be fully compatible with digital printing, resulting in blurred or unclear images.

Discover now: Envelope Printing – Custom Envelopes for Business & Personal Use

Canvas Bag Finishing Techniques

Finishing Techniques are procedures applied to reinforce the bag's structure and durability, focusing on details like handles, edges, and bottom. There are three main methods:

- Hand Sewing: This is a manual technique using needle and thread to sew details. This method creates a handmade, unique feel and high aesthetic value, but in return, the cost and production time are higher.

- Heat Pressing: Uses high temperature to fuse components (handles, edges, bottom). This method is fast, convenient, and low-cost. However, its durability is not as high as hand-sewing, and it may cause fabric deformation.

- Film Lamination : Applies a thin film layer to the surface of the canvas bag to enhance durability, water resistance, and ease of cleaning. The drawbacks are that it makes the bag stiff, less breathable, and may feel hot during use.

Learn more:

- Business Card Printing – Custom & Professional Solutions

- Letterhead Printing – Custom Branded Stationery for Your Business

Production & Quality Assurance Process at Alona

At Alona, the canvas bag production process is standardized into 5 steps, ensuring consistent quality and easy tracking for customers.

Step 1: Order & Quotation

Customers visit the website, select material, size, and quantity to get a price quote and estimated completion time, then click “Order Online” or “Request a Quote.”

Attach your design file when ordering. If you don’t have one, Alona offers design support (with service fee).

Note: Production time starts once the order and deposit are confirmed. Prices exclude design fees and VAT.

Step 2: Order Confirmation & Design

- For customers with ready designs: Proceed to contract signing and production preparation.

- For customers without designs: Provide detailed information for Alona’s team to create sample designs.

Step 3: Sample Production & Quality Check

Alona creates a real printed sample for review and approval. Once confirmed, production moves forward.

Step 4: Deposit & Mass Production

After deposit payment, bulk production begins according to the approved sample.

Step 5: Delivery & Final Payment

Upon completion, Alona contacts the customer for delivery. Customers inspect the products and pay the remaining balance.

A beautiful canvas bag is more than just a stylish accessory it’s a powerful way to express your brand identity with elegance and sustainability. If you’re looking for a reliable canvas bag printing manufacturer that offers custom designs, high durability, and premium quality, look no further than Alona - a trusted canvas bag printing workshop in Ho Chi Minh City. With years of experience, Alona is committed to delivering durable, beautifully printed, and precisely crafted products, ensuring every order meets your expectations. Contact Alona today for a free consultation, quick quotation, and sample printing before production!

Read more: Custom Parking Ticket Printing Services from Vietnam

Thẻ