Bạn muốn in ấn gì ?

PP Woven Bag Printing - Custom Woven Polypropylene Bags in Vietnam

Woven Polypropylene (PP) bags are a durable, high-strength, and reusable packaging solution favored by businesses. However, choosing the correct fabric weight, weave density, and suitable PP woven bag printing technology (such as Flexo or BOPP Gravure) can often be challenging. This article provides comprehensive knowledge on the structure, technical specifications, and reinforcement options to help you make the optimal decision for your products.

What Is PP Woven Bag Printing?

A Woven PP bag is a packaging product created by weaving Polypropylene (PP) plastic threads together. This process forms a strong, durable "fabric," which is then processed and printed to create the finished bag.

Thanks to this special structure, woven PP bags stand out for their extremely high load-bearing capacity, effective water resistance, and multiple reuses.

They are widely popular due to the following outstanding characteristics:

- Superior Material: Made from virgin PP resin, the bags are durable, lightweight, odorless, and can withstand high temperatures.

- Exceptional Durability: They can handle heavy loads, are tear-resistant, and completely waterproof, making them ideal for packaging large-volume products.

- High Flexibility: Easily customized in terms of size, color, and style. Bags can be printed in up to 1 to 6 colors, making your brand stand out.

- Eco-Friendly Solution: With a long lifespan and the ability to be recycled and reused many times, woven PP bags are a sustainable choice that helps businesses reduce plastic waste.

Key considerations when ordering PP woven bag printing

When deciding to print woven PP bags, selecting and defining the technical specifications is a crucial step, directly influencing the final product's quality, durability, and production cost. To ensure the bag meets your specific usage requirements and brand needs, it is essential to thoroughly examine the basic components. The following section details important considerations regarding material and bag structure:

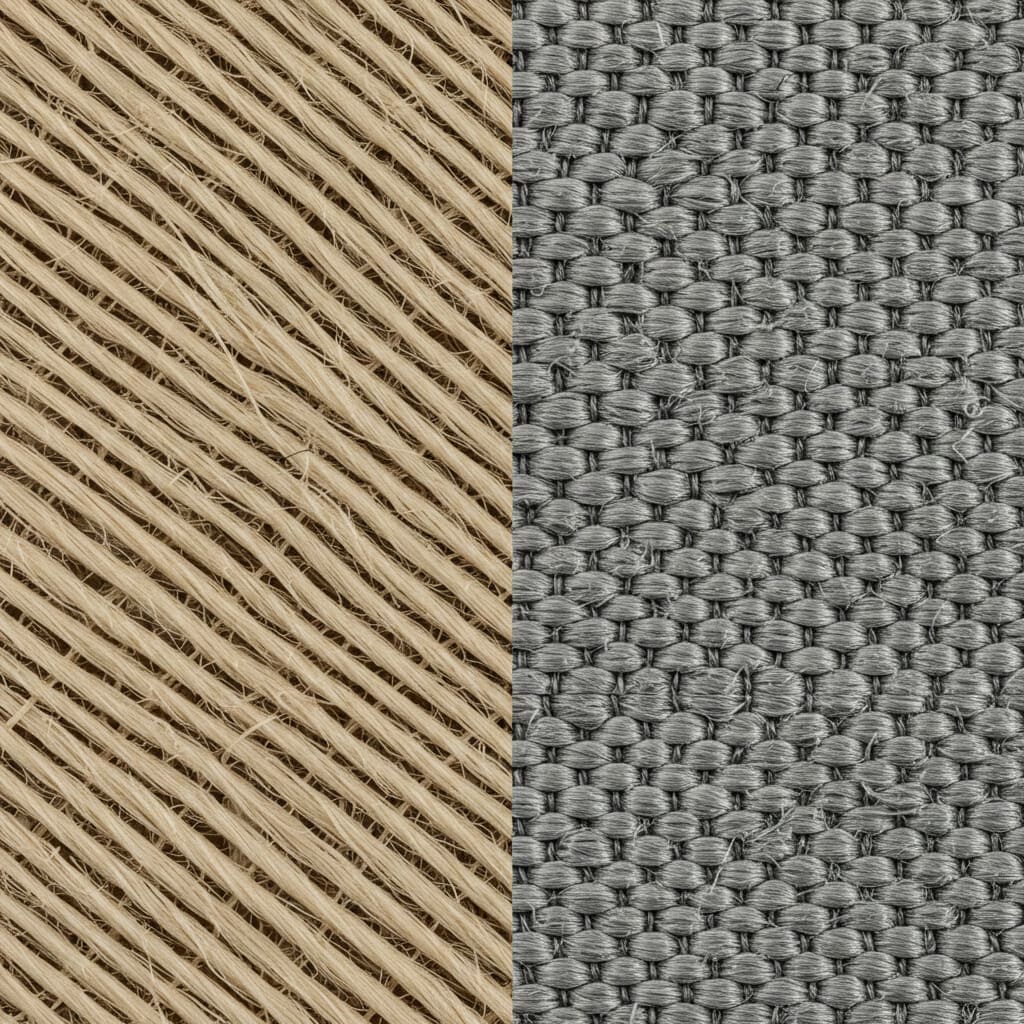

Fabric GSM / Density / Denier Choices

Selecting the correct technical specifications—including Denier (D), Weave Density, and Fabric Weight (GSM)—is paramount for producing a woven PP bag. Understanding these three factors will ensure the bag meets the precise requirements for durability and intended use.

Weave Density and Fabric Weight (GSM): These two factors determine the tightness and overall thickness of the fabric:

- Weave Density: The number of woven threads per unit area. Higher density means the fabric is tighter, more durable, and less prone to stretching, enhancing tear resistance.

- Fabric Weight (GSM - grams per square meter): The weight of the fabric per square meter. A higher GSM indicates a thicker and heavier fabric, reflecting better overall durability.

Denier (D): Thread Thickness: This is the unit of measure for thread thickness/mass. A higher D index means the thread is thicker and more durable.

- 75D: Thin thread, suitable for thin, lightweight products.

- 150D, 300D and above: Thick, sturdy thread, ideal for bags requiring high load-bearing capacity.

To choose the correct specifications, you need to consider the load capacity and product requirements:

- Lightweight, Fashion, or Promotional Bags: Choose thin threads with low Denier and moderate weave density.

- Heavy-Duty, Travel, or Supermarket Bags: Require thick threads with high Denier (e.g., 150D, 300D) and high weave density to ensure superior load capacity and durability.

Lamination / Coating Options

Lamination is a crucial finishing process where a thin layer of synthetic plastic film (typically PET, BOPP, or PVC) is applied to the surface of the woven PP bag after printing. This film is tightly bonded to the fabric using heat and pressure or specialized adhesive.

Lamination offers exceptional benefits, not only for durability but also for aesthetics:

- Comprehensive Protection: The film acts as "armor," providing absolute water resistance, scratch resistance, and color fade limitation for the ink, thereby extending the packaging's lifespan.

- Enhanced Aesthetic Value: Options for glossy, matte, or special-effect laminations help your packaging become more prominent, premium, and professional, significantly elevating the product's visual appeal.

Bag Structure Types

Woven PP bags offer high flexibility, allowing customization of the following key technical parameters:

- Main Material: Premium woven PP fabric, known for its durability and heavy load-bearing capacity.

- Dimensions: Fully customizable based on production requirements. Common sizes range from 40 cm to 70 cm (width) and 58 cm to 130 cm (length).

- Color: Highly diverse and produced according to specific requirements to match brand identity.

- Fabric Specifications: The bag's durability is determined by the weave density, typically measured by the number of threads per 10 cm2. Examples of common weave densities: 36×36/10 cm2, 40×40/10 cm2, or 48×48/10 cm2.

Reinforcements & Features

Woven PP bags can be enhanced with multiple special features and reinforcements to boost durability, protection, and utility. These films and smart accessories not only make the bags sturdier but also contribute to improved aesthetics and environmental friendliness.

- BOPP Lamination: Coating the surface with BOPP (Biaxially Oriented Polypropylene) film helps increase durability, moisture resistance, scratch resistance, and supports sharp image printing.

- PE Liner: Adding an inner PE (Polyethylene) liner prevents water and moisture penetration - especially useful for products that require dry storage.

- Traceability (QR Code): Integrating QR codes or other smart printing solutions helps easily manage, authenticate goods, and increase brand transparency.

- Reusability & Printability: The durable structure allows for multiple reuses, while the smooth surface supports clear, colorfast printing of logos and images.

Printing Technologies for PP Woven Bags

There are two primary printing technologies applied to woven PP packaging, each suited to different quality and budget requirements: Flexo Printing and Gravure Printing (BOPP).

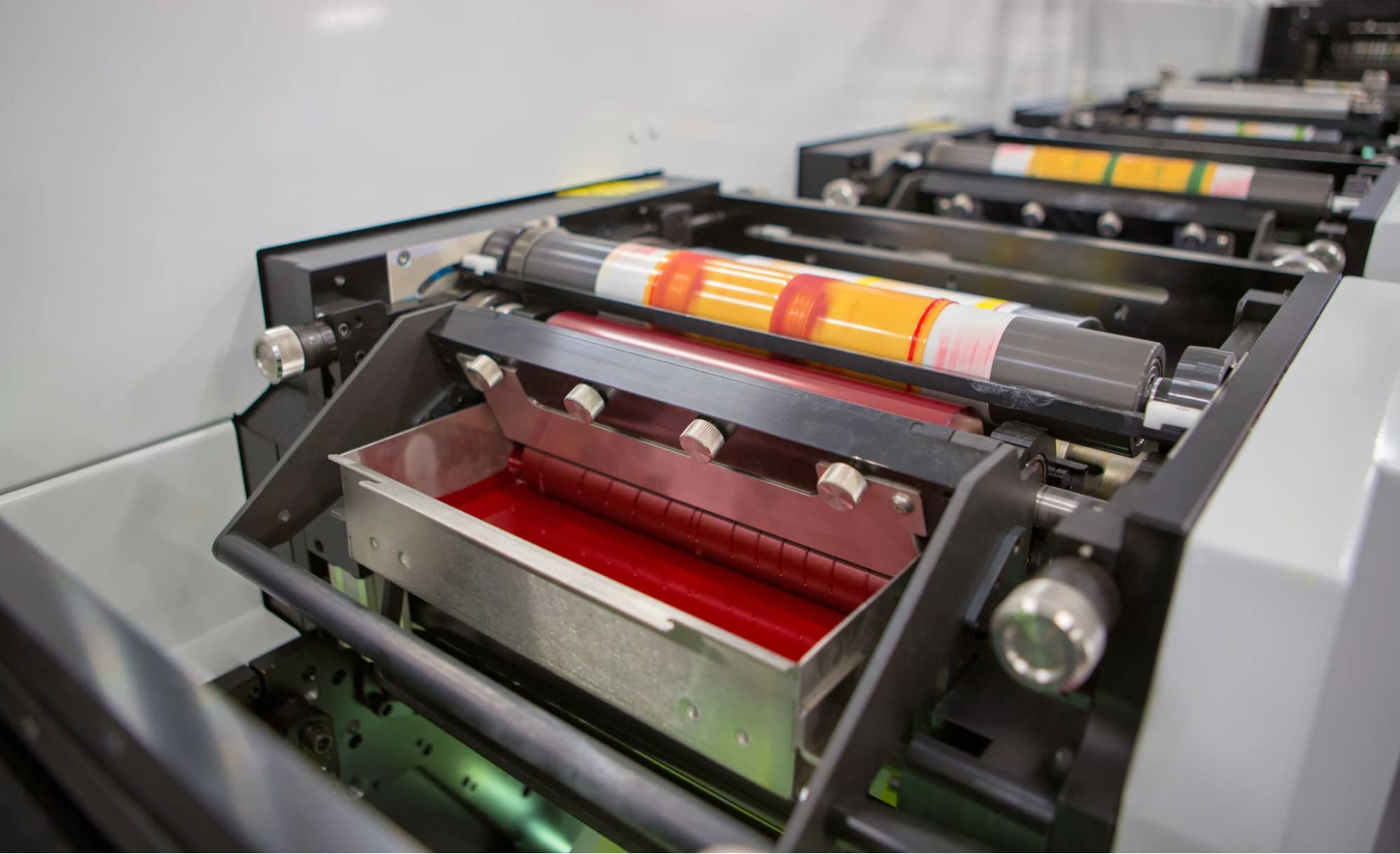

Flexo Printing (Flexographic Printing)

This is a relief printing method using a flexible polymer printing plate (Flexo plate) to transfer ink directly onto the bag surface. Flexo is the ideal choice for basic needs:

- Application: Suitable for simple designs, text content, logos, or block images that do not require very high detail. Often used for unlaminated or lightly laminated woven PP bags.

- Speed and Cost: Highly cost-effective for large-volume orders due to high printing speed.

- Durability: Flexo ink has good adhesion on woven PP material, ensuring color fastness.

- Flexibility: Can print on one or both sides of the packaging.

Discover now:

- Business Card Printing – Custom & Professional Solutions

- Letterhead Printing – Custom Branded Stationery for Your Business

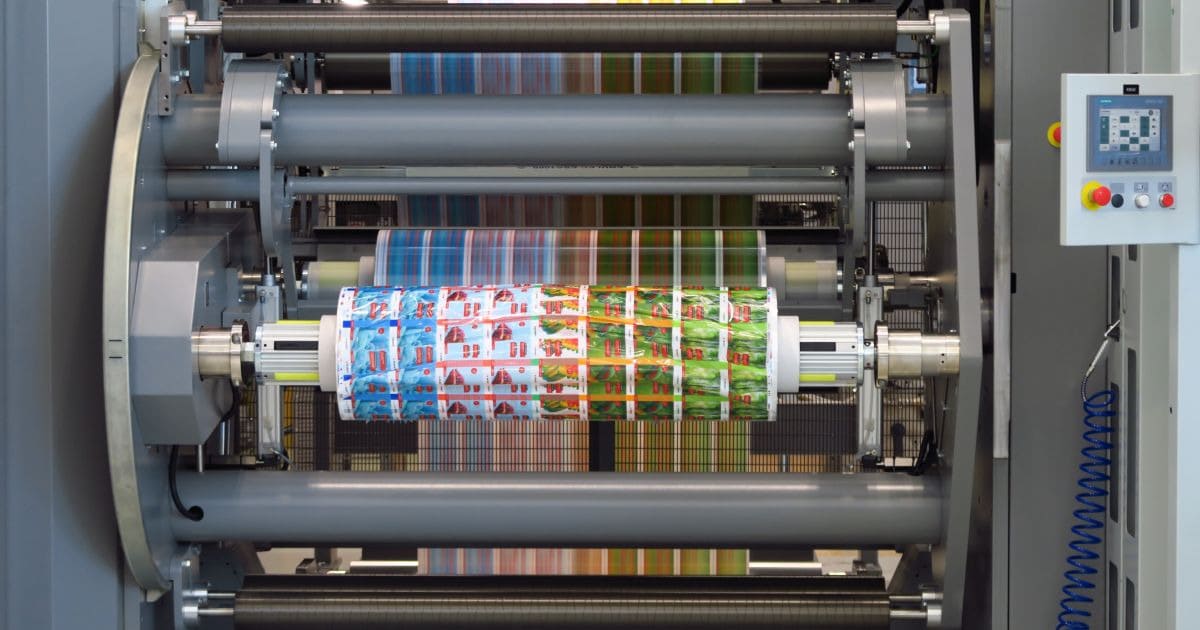

Gravure Printing - BOPP Packaging Printing

Gravure is an intaglio printing method that creates high-end products by printing directly onto the BOPP film first, which is then laminated onto the woven PP fabric.

- Application: Used for high-end, composite woven PP packaging (BOPP/PP) that demands absolute print quality and aesthetics.

- Superior Image Quality: Delivers sharp, highly detailed images, vibrant, true-to-life colors (photographic quality), and smooth color transitions.

- High Product Durability: The multi-layer structure protects the printed image, providing excellent scratch and water resistance, extending the packaging lifespan.

Learn more: Custom Parking Ticket Printing Services from Vietnam

Contact Alona for High-Quality PP Woven Bag Printing Service

Alona is a specialized partner offering high-quality woven PP bag printing and manufacturing services, from basic designs to complex composite products. We help businesses turn packaging ideas into reality by providing diverse options for materials, fabric weight, and printing technology. Alona focuses on reinforcement solutions like BOPP Lamination (for waterproofing and aesthetic enhancement) and PE Liner (for maximum moisture resistance), ensuring your packaging has superior durability and premium visual appeal.

Customers should choose Alona because we are committed to delivering simplicity and absolute quality throughout the ordering process:

- Expert Consultation: Our team of experts will analyze your product's load-bearing needs and budget to suggest the optimal technical specifications (such as Denier, Fabric Weight, and Weave Density).

- Excellent Print Quality: We apply advanced printing technology, including BOPP Gravure, ensuring the images on the bag are sharp, detailed, and true-to-life in color, significantly elevating your brand presence.

- Simple and Efficient Process: Alona is committed to a fast-paced workflow, helping you save time and cost, and ensuring orders are completed and delivered on schedule.

Woven PP bags are a strategic choice for packaging due to their durability and high flexibility. To ensure your bags achieve maximum quality, from load capacity to image sharpness, trust in the expertise of Alona. Contact Alona today for in-depth consultation and the best quotation for your business's woven PP packaging solution.

Read more: Premium Canvas Bag Printing in Vietnam - Custom Canvas Bags by Alona

Thẻ

.jpg?t=1988460728)